A walk in cooler not working can bring a commercial operation to a standstill, creating immediate risks for food safety, inventory loss, and compliance. Whether you manage a restaurant, bar, grocery store, floral business, or cafeteria, your cooler is one of the most critical systems in your facility. When temperatures begin to rise unexpectedly, it puts both your product and your profitability at risk. Because commercial coolers run continuously in demanding environments, small issues can progress quickly, making early attention essential.

Understanding the potential causes helps your team respond faster and determine when to bring in a trained technician. Commercial cooling systems depend on a combination of electrical, mechanical, and airflow components, and even minor deviations can affect temperature consistency. Below, we explore some of the most common reasons a walk in cooler not working situation may occur and why professional evaluation is often required to protect your equipment and inventory.

Common Reasons a Walk In Cooler Not Working Can Disrupt Operations

Commercial walk in coolers are designed for reliability, but they operate in high-demand environments where temperature fluctuations, high traffic, and heavy usage can expose weaknesses. When your cooler stops maintaining the correct temperature, it may signal the early stages of a walk in cooler not working issue, whether caused by a simple setting problem or a component starting to fail.

The sections below outline the most common factors that lead to performance drops, helping you understand what may be happening before calling a professional for a full assessment.

1. Incorrect Temperature Settings or Control Issues

Temperature controls and sensors ensure the cooler maintains a consistent climate. When these controls drift out of calibration or are accidentally changed, the system may run too warm or cycle inconsistently. This is common in busy commercial kitchens where multiple team members access the cooler daily. If the reading on the display does not match the actual temperature, the issue may involve the sensor or control board rather than the cooling components themselves.

Before assuming a major malfunction, verify that the setpoint has not been adjusted by mistake and that nothing is blocking the sensor. If the issue still resembles a walk in cooler not working scenario, deeper diagnostics should be performed by a trained technician to ensure the controls are communicating properly with the refrigeration system.

2. Dirty or Blocked Condenser Coils

Condenser coils release the heat drawn out of the cooler. In commercial environments, grease, dust, and debris accumulate quickly on these coils and restrict heat dissipation. When this happens, your refrigeration system must work harder to maintain temperature, and over time, it may fail to keep the cooler cold, often triggering the early symptoms of a walk in cooler not working. This is a common contributor when teams notice the compressor running longer than usual or the cooler slowly warming.

What to look for:

- Coils become covered with grease and debris in high-traffic food service environments.

- Blocked coils force the compressor to run longer, increasing stress and heat.

- Reduced airflow leads to gradual temperature increases inside the cooler.

Light surface-level cleaning of accessible coil areas may help reduce strain, but deeper coil maintenance should be performed by a professional who understands commercial refrigeration safety protocols and can check for underlying mechanical stress, especially when a walk in cooler not working situation continues to develop.

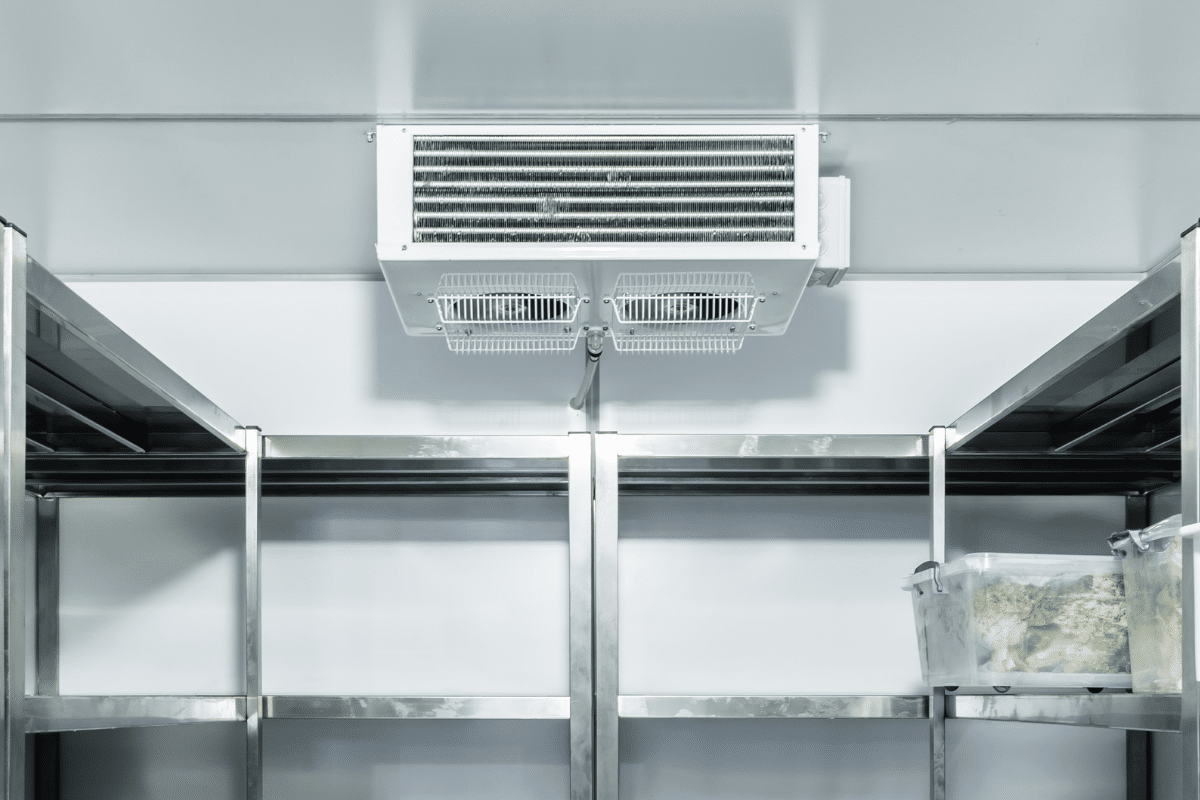

3. Evaporator Problems and Airflow Restrictions

The evaporator coil inside the cooler absorbs heat and circulates cold air. When airflow becomes restricted by frost, debris, or blocked pathways, the system may struggle to maintain even temperatures. Frost accumulation can also occur if warm air frequently enters the cooler or if the defrost cycle is not functioning as designed. Airflow disruptions often present as warm spots inside the cooler or inconsistent temperatures between shelves.

What to look for:

- Obstructed airflow reduces cooling efficiency inside the walk in.

- Frost buildup can indicate issues with the defrost cycle or door sealing.

- Restricted circulation leads to uneven temperatures across the cooler.

If airflow issues continue after clearing simple obstructions, a professional should evaluate the evaporator system to determine whether it’s contributing to a walk in cooler not working. This helps prevent more extensive failures caused by overworking the equipment.

4. Worn Door Gaskets and Air Leaks

Door gaskets endure constant contact in commercial settings, especially in kitchens where doors are opened frequently. When gaskets wear out or become torn, warm air enters the cooler, humidity rises, and frost forms on the evaporator, often creating the early signs of a walk in cooler not working situation. Even a small gap can significantly raise the internal temperature. These issues often develop gradually, making routine visual checks important to maintaining energy efficiency and preventing inventory concerns.

What to look for:

- Damaged or loose gaskets allow warm air to enter the cooler.

- Moisture accumulation can trigger excessive frost on internal components.

- Temperature recovery becomes slower after each door opening.

|A technician can inspect door alignment, gasket integrity, and sealing pressure to ensure the door is functioning correctly, especially if these issues are contributing to a walk in cooler not working during daily operations. In high-usage businesses, gasket replacement is a normal part of preventative maintenance.

5. Failing Fan Motors

Fan motors circulate air over both the condenser and evaporator coils. When these motors begin to fail, airflow drops, leading to major temperature inconsistencies. Businesses might notice unusual noises, slower cooling, or zones inside the cooler that never seem to reach the correct temperature. Because fans operate continuously, motor wear is common over time.

- Weak airflow causes poor temperature distribution inside the cooler.

- Loud or unusual noises may indicate bearing or motor issues.

- Failing motors force compressors to run longer than normal.

If airflow problems persist, a technician should inspect the fan assembly and electrical connections to determine whether the issue is contributing to a walk in cooler not working. Addressing fan motor issues early can prevent more severe strain on the refrigeration system.

6. Compressor Performance Issues

The compressor is the core of any commercial cooling system. When it struggles, the cooler will quickly rise in temperature. Warning signs may include unusually loud operation, short cycling, or long periods of running without achieving proper temperatures. Because compressors operate under pressure and rely on electrical and mechanical components, only trained professionals should diagnose issues.

What to look for:

- Short cycling can indicate electrical or mechanical challenges.

- Extended run times may signal internal wear or system imbalance.

- Warm temperatures often appear quickly when compressors malfunction.

If your walk in cooler not working and involves compressor strain, prompt professional inspection is crucial to reducing downtime and preventing damage to other components.

7. Refrigerant Problems

Refrigerant is essential for cooling performance. When levels drop due to leaks or system imbalance, temperatures rise, and the compressor must work harder to compensate. Commercial walk ins often show signs such as gradual temperature increases or oil residue near tubing. Refrigerant issues require immediate professional attention, as only certified technicians are permitted to handle or recharge refrigerant due to federal regulations.

What to look for:

- Low refrigerant can lead to weak cooling and ice accumulation.

- Oil residue may indicate a leak in the refrigeration system.

- Irregular cooling cycles often appear as refrigerant levels drop.

If refrigerant loss is suspected, a licensed technician should evaluate the system to avoid compressor damage and ensure compliance with EPA handling requirements, especially when it contributes to a walk in cooler not working condition.

8. High Ambient Temperature or Poor Ventilation

Commercial kitchens and prep areas often generate significant heat. If your walk in cooler’s condenser unit is located in a confined or unventilated space, that heat can overwhelm the system. Poor airflow around the condenser prevents it from releasing heat effectively, causing temperatures inside the cooler to rise even if all components are functioning normally.

What to look for:

- Heat-producing equipment near the condenser limits efficiency.

- Poor ventilation around the unit slows heat dissipation.

- Temperature fluctuations worsen during peak business hours.

Ensuring the condenser has adequate ventilation may improve performance, but equipment placement issues often require professional evaluation to prevent recurring heat-related failures, especially when they contribute to a walk in cooler not working during peak business hours.

If your system shows persistent temperature problems or needs expert evaluation, scheduling professional commercial appliance repair with Handler Appliance or your local servicer ensures your business receives the proper support to restore performance quickly and safely.