A commercial ice machine not working can quickly disrupt daily operations in restaurants, bars, healthcare facilities, and hospitality environments. Ice is often taken for granted until production stops entirely. When a machine is not making ice, the issue is rarely random. Most failures trace back to maintenance concerns, worn components, or system-level problems that require professional attention.

This guide explains the most common reasons this situation occurs, what symptoms to watch for, and why timely service matters. The focus is on education and awareness, so business owners can understand what may be happening without attempting unsafe or technical repairs.

Why a Commercial Ice Machine Not Working Usually Means Ice Production Has Stopped

When technicians describe commercial ice machine failures, they are typically referring to a unit that has stopped producing ice altogether or is producing ice at a drastically reduced rate. Ice machines rely on a balance of water flow, refrigeration, airflow, and electronic controls. If any one of these systems fails, ice production can shut down.

Below are the most common causes, starting with simpler issues and moving toward more complex system failures.

1. Environmental and Installation Factors

Ambient temperature and surrounding equipment can affect ice production. Ice machines installed near heat-producing appliances or in poorly ventilated spaces may struggle to function properly.

In some cases, what appears to be a commercial ice maker not working is actually a response to an unsuitable operating environment that requires professional assessment.

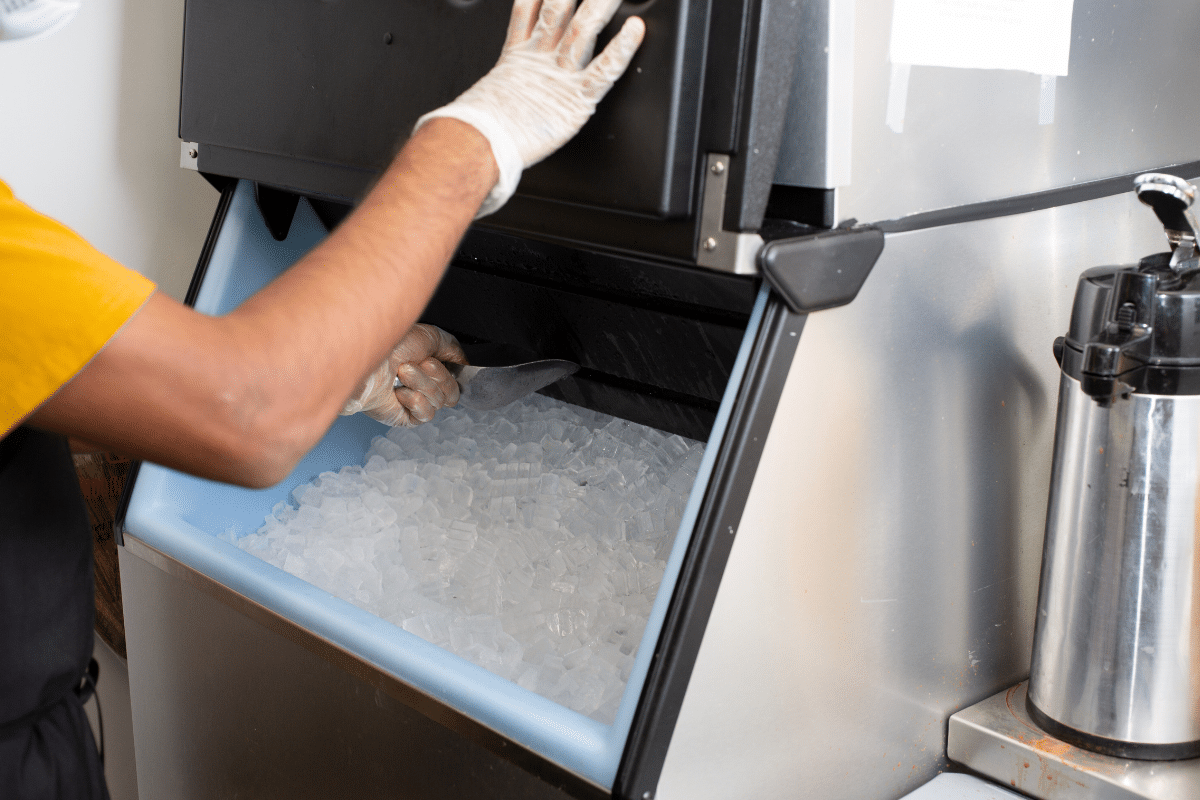

2. Ice Bin and Storage-Related Shutdowns

Ice machines are designed to stop producing ice when the storage bin is full. If bin sensors malfunction, the machine may believe the bin is full even when it is empty.

This can create confusion for operators who see a commercial ice machine not working but find no obvious mechanical issue. Sensor calibration and replacement should be handled by a technician familiar with the equipment.

3. Water Supply Problems

Water is the foundation of ice production. If water cannot properly enter the machine, ice cannot form. Many commercial ice maker not working service calls involve water-related concerns.

Common water-related contributors include:

- Restricted or inconsistent water flow

- Mineral buildup is affecting internal water pathways

- Sediment accumulation from hard water conditions

A visual inspection for obvious leaks or external water issues is safe, but internal water system problems should always be handled by a professional to prevent damage or contamination.

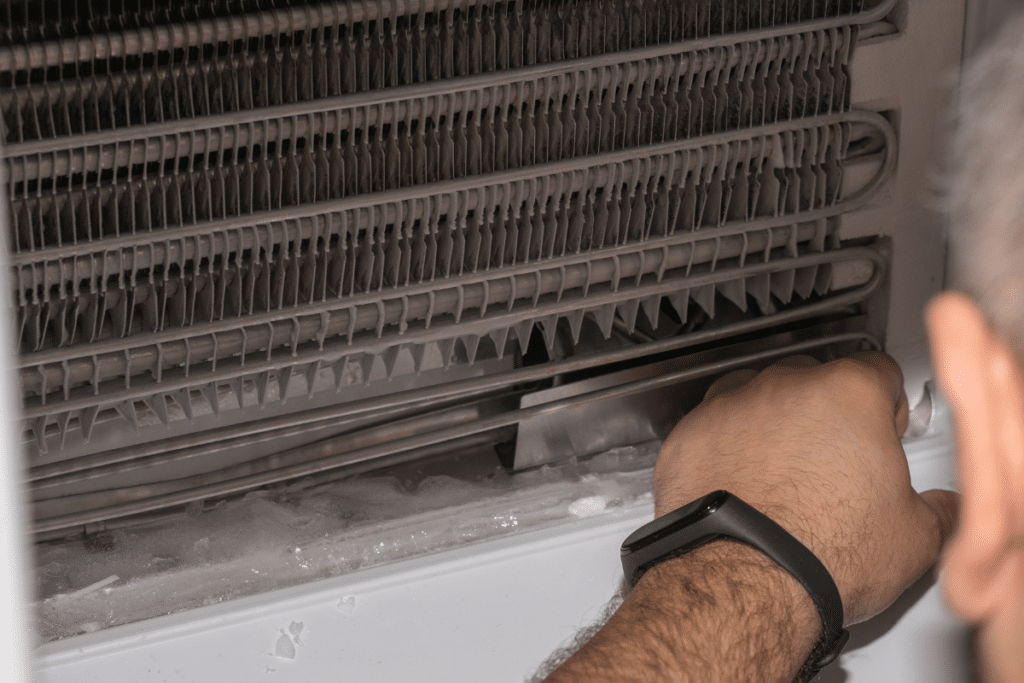

4. Dirty or Blocked Airflow Components

Commercial ice machines rely on proper airflow to remove heat from the refrigeration system. When airflow is restricted, the unit may shut down or fail to complete an ice-making cycle.

Airflow-related issues often involve:

- Dust and grease buildup on exterior ventilation areas

- Obstructed intake or exhaust paths around the unit

- Overheating that triggers safety shutdowns

Keeping the area around the machine clear is a safe preventative step. Internal airflow or fan issues, however, require trained service technicians.

5. Scale and Mineral Buildup

Hard water is one of the leading contributors to long-term ice machine failure. Mineral deposits can coat internal surfaces, interfere with water flow, and reduce freezing efficiency.

Common effects of mineral buildup include:

- Reduced ice production over time

- Cloudy or misshapen ice

- Increased strain on internal components

Regular professional maintenance helps control scale buildup and extends equipment lifespan. Once heavy buildup occurs, ice production may stop entirely.

6. Ice Thickness or Harvest Cycle Issues

Ice machines follow a precise freeze and harvest cycle. If the machine cannot properly sense when ice is ready to release, production may stop. This is another frequent reason a commercial ice machine’s not working condition develops.

Symptoms may include ice that never fully forms, ice that will not drop into the bin, or cycles that run endlessly without producing usable ice. These issues are typically tied to sensors or control logic and should be evaluated professionally.

7. Control Board or Electrical Failures

Modern commercial ice machines depend on electronic control boards to manage timing, temperature, and safety functions. A failure in these systems can result in a commercial ice machine not working even though the unit appears powered on.

Common signs include unresponsive displays, erratic behavior, or cycles that stop unexpectedly. Electrical diagnostics should never be attempted without proper training, as they pose safety risks and can worsen the problem.

8. Refrigeration System Problems

The refrigeration system is responsible for removing heat so water can freeze. When this system is compromised, the machine may run but never make ice.

Refrigeration-related warning signs may include:

- Inadequate cooling prevents water from freezing

- Extended run times with no ice output

- System strain that worsens over time

Refrigeration issues are complex and can involve sealed components. These problems always require professional diagnosis and repair to avoid further system damage.

Why Ignoring Ice Production Problems Can Lead to Bigger Issues

Continuing to operate a machine that is no longer producing ice can lead to additional failures. Motors, compressors, and controls may experience unnecessary stress, increasing repair costs and downtime.

Much like a broken walk-in cooler, ice machine failures tend to worsen when left unaddressed. Early service often prevents secondary damage and keeps operations running smoothly.

When Professional Service Is Necessary

If you have a commercial ice machine not working properly due to refrigeration, electrical systems, or internal components, professional service is required. While basic cleaning and visual checks are part of routine care, most ice production failures go beyond surface-level maintenance.

If your ice machine has stopped producing ice or performance has declined, it may be part of a larger system issue similar to other commercial refrigeration failures. Working with Handler Appliance for commercial appliance repair in Northern New Jersey ensures the problem is addressed safely and correctly.